FREE SHIPPING when you spend $500+

Below $500: Flat rate of $14.99 for shipping.

Track Your OrderNeed Help? Call Us: 918-512-1281

- FOR THE DRIVER

- FOR THE PIT/SHOP

- FOR THE CAR

- GEAR & MERCH

Free shipping when you spend $500+

FREE SHIPPING when you spend $500+

Below $500: Flat rate of $14.99 for shipping.

Free shipping when you spend $500+

As an exclusive dealer for AST Suspension we work with the designers at the factory in Holland to design a suspension system tailored to your specific needs. Every coilover from AST is custom made for the application. Nothing is off the shelf.

If you have any questions we can help. You can drop us a line here and one of our staff humans can help get you an answer!

We offer suspension systems for most cars found at North American track events. BMW (E30, E36, E37, E38, E40, E85, E86, and others), Ford Fiesta, Focus, Mustang (S550), Honda (Civic, Civic Type R, S2000, AP1, AP2), Hyundai (Elantra i30N PD), Lotus (Elise, Exige), Mazda MX5/Miata (NA, NB, NC, ND), RX8, Mini (R50, R512, R53, GP1, R55, R56, R57, R58, R59, GP2, F56, GP3, Countryman, Clubman), Mitsubishi, (Evo4, Evo5, Evo6, Evo7, Evo8, Evo9, Evo10), Nissan (200SX, 240SX, S14, S15, 350Z, 370Z, GTR R35), Porsche (911, 944, 964, 968, 991, 996, 997, Cayman, Boxster, and others), Subaru (Impreza, WRX, WRX STI, BRZ), Toyota (GT-86, FT86, Scion FR-S, Supra, A80, A90, Yaris) and the Volkswagen (Golf, Scirocco).

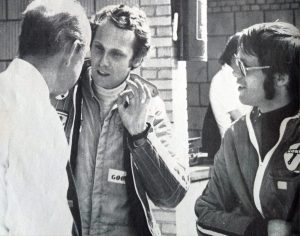

The story of AST begins with Piet Kreeft. Piet started his career with KONI Suspension in 1965 working for their motorsport department supporting professional racing all over the world. Here he is, pictured right, speaking with F1 legend Niki Lauda, center, in 1969.

After 15 years at KONI Piet decides to branch out on his own and in 1980 he forms Aragosta Suspension which specialized in motocross and GP racing bikes, where they soon become leaders in both of these areas. Aragosta then gets involved in suspension for vehicles and were present at World Rally championships, Kartcross and Touring car events where they set records in the Paris-Dakar Rally, in both the T1 and T2 categories.

In 1989, aided by the suspension designed by Piet, Emmerson Fittipaldi became INDYCAR 500 World Champion. Piet supported INDY CAR chassis and suspension development for over a decade.

In 2000 Piet forms AST Suspension with the manufacturing expertise of Peter Smits & Gerard Smits of Smits Factory to manufacture every component. Together Piet and the Smits combined the technical expertise of suspension design along with the unparalleled quality control and manufacturing flexibility unlike others in the suspension industry.

In 2007, AST brings these decades of suspension design and manufacturing expertise to the North American market and in 2010 is selected as the damper provider of the GRAND-AM Continental Tire Sports Car Challenge. The GRAND-AM Continental Tire Sports Car Challenge ran in the United States from 2000 to 2014 and was split into two classes, Grand Sport (GS), intended for large capacity GT-style cars, and Street Tuner (ST), consisting of smaller sedans and coupes.

If you are considering upgrading your suspension, AST Suspension needs to be on the short-list. Every AST coilover manufactured is designed specifically with the user and application in mind.

A couple things we need to know before designing a suspension system just for you:

Find the AST Suspension system just for you. Using the link you can select your car make/model then can investigate the three types of AST coilover kits we offer. The 5100 (single adjustable (rebound)), the 5200 (double adjustable (rebound/compression)) and the 5300 (triple adjustable (rebound/compression), shock velocity)). Once locating you shock you will be prompted to enter the above information. Again, if you have any questions during this process you may reach out to us here.

Learn more about the technical details and specifications of the 5100, 5200 and 5300 shock by checking out this article we generated.

AST Suspension brings decades of motorsports and suspension/chassis design experience the table. You will love your kit once installed, helping make the car more predictable, giving you confidence and finding grip you didn’t know you had.

AST is the leader in monotube shocks and inverted technology. (In this article we explain shock/damper basics and their role in chassis tuning). At a high level, a monotube shock is superior to the twintube design because the hydraulic fluid and nitrogen gas never come into contact with each other. Further, the pressure of the nitrogen may be regulated to assist in damping force. This is an area where AST excels. Many chassis designers will choose a spring rate, then add the shock later. At AST they select valving and nitrogen pressures so the damping force is actually part of the desired spring force they are targeting. So they know what spring rate they need, then select a spring AND damper that will achieve this overall spring rate. Other chassis tuners will select a spring to achieve the desired overall spring rate, then add the damper as an after thought. The monotube shock also allows the use of a larger piston, increasing the damper performance and sensitivity felt by the driver, all this added together produces more grip, gives more control and driver feedback from the vehicle.

In the inverted design the tubes containing the fluid and gas are mounted upside down as opposed to an OE standard shock. In extreme conditions (like on a track) this moves the fluid and gas away from the wheel hub which can get heated from the brake pad/rotor assembly. This allows the shock to run cooler helping it to perform at peak for much longer. Mounting it inverted also removes unsprung weight by mounting the heavier tube assembly containing the fluid and gas to the chassis as opposed to the control arms. This design makes for a very stiff strut assembly allowing it to take the abuse it will see in a typical track situation. Mounting inverted also provides for better suspension geometry under the heavy lateral and braking loads we see in a road course environment.

All AST topmounts are made of the highest quality materials available. The plates are made out of an exotic high grade aluminum. The bearing plus its carrier are made within very small tolerances that results in a unique noise free pillowball setup. AST uses the same materials and bearings as used within the aviation industry. This helps make the AST top mounts almost free of maintenance. A key advantage of the AST topmounts is you can get more negative camber than available using the OEM topmount.

All 5100 series shocks will work with OEM topmounts and prices listed are with OEM topmounts. (Email us at info@calltogrid.com for pricing on the 5100 with the AST topmount). Pricing shown for the 5200 and 5300 shocks include the AST topmounts.

All of the AST suspension range have been very popular with the Honda S2000 (AP1/AP2) public since the S2000 debuted in 1999. Different valving and settings have been developed for different applications. Whether driving on the streets, trackday/HPDE or racing, there is a different setup just for you!

After years of testing, driving, performing and winning races, we know the Honda S2000’s suspension like no other.

In 2001 the MINI Cooper nameplate came back to the world market with the MINI R50 Cooper (more horsepower) and the R50 One. (less horsepower) Later that year MINI introduced the R53 Cooper S and people immediately began racing it. This had everything to do with the Rover Mini’s racing heritage. These cars were like go karts. The short wheelbase helps.

In 2006 MINI introduced a complete new arsenal of new models, convertibles, station, hatchbacks, coupe’s, SUV’s and roadsters. These are the R55, R56, R57, R58 and the R59, R60 and R61.

AST started racing with MINIs back in 2002 (focused on the hatches people were putting on track). This started off in the UK with the MINI Challenge. This grew to be one of the most successful spec racing series in the UK where AST Suspension supplied the 5100 as the spec damper for that championship. As a result of this success, AST has continued supplying race teams and amateur racers with suspension kits for their newer MINI R56, R55 and other models.

When the latest model, F56 MINI came out, AST jumped onto that platform and developed one of the first coilover kits for that car. AST has been in MINI racing for over 18 years and we know what to do with hot hatches like the F56 and the F56 JCW. The F56 kit AST has developed can be ordered as a true coilover rear system (spring over damper) or as a non coilover rear system (Spring in OE position). All our kits, 5100, 5200 and 5300, are made to order for the application. AST valves them custom for the customer together with the correct spring rates.

If you are considering upgrading your shocks AST Suspension needs to be on the short-list. Every AST coil over manufactured is designed specifically with the user and application in mind. Nothing is off the shelf. We design and manufacture the shocks based on the car, driver goals (i.e. trackday/HPDE, time trial/time attack or wheel-wheel racing), tire/brake pad combination, any added aero and even driving style of the driver. AST Suspension brings decades of motorsports and suspension/chassis design experience to the table. Let us design a coil over you will love, making the car more predictable, giving you confidence.

We make it very easy to locate the shock best suited to your needs. Simply click the link below, select your car make, then car model and then select the AST Suspension damper/shock best suited to both your budget and your needs. We offer AST Suspension dampers for most car makes found at North American track events: BMW, BMW-Mini, Ford, Honda, Hyundai, Lotus, Mazda, Mercedes, Mitsubishi, Nissan, Porsche, Subaru, Toyota and Volkswagen. Once you’ve selected the AST damper you want then just provide us some additional information so we can design a suspension system tailor made to your application. We’ll need total car weight with driver, tire make/model, engine HP, any aero mods you’ve made and any other other information you’d like to share such as the series you run in or your driving style.