FREE SHIPPING when you spend $500+

Below $500: Flat rate of $9.99 for shipping.

Track Your OrderNeed Help? Call Us: 918-512-1281

- FOR THE DRIVER

- FOR THE PIT/SHOP

- FOR THE CAR

- GEAR & MERCH

Free shipping when you spend $500+

FREE SHIPPING when you spend $500+

Below $500: Flat rate of $9.99 for shipping.

Free shipping when you spend $500+

The racing shock absorber, or damper (proper term), may be one of the most mysterious elements in chassis design and tuning. In chassis setup/tuning, selecting shocks should be one of the last things you do. Choosing your ride height, spring rates, sway bars, setting camber and toe and then scaling the car to get a near 50/50 cross weight should all be done first. Changing coilovers will result in you needing to re-dial in your ride height and re-scale the car. In general, a good coilover will not help improve the handling of the car, but will make the car feel more compliant helping to provide the driver with confidence in the car.

The racing shock is part of what is called in physics a “spring-damper system”. The springs allow the wheels to move up and down to absorb bumps in the road helping to smooth out the ride for the passengers, while the dampers prevent the springs from bouncing up and down forever. (I think we’ve all seen that old Cadillac or Crown Vic bumping up and down going down the freeway. This is because the shocks on that car are “spent” or no longer providing any dampening).

The primary function of the dampers, is to control the energy as it enters and exits the springs, which when compressed (“bump”) and then released (“rebound”) have a natural tendency to overshoot their original length as they release the energy.

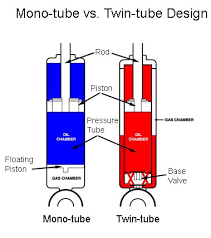

Shock absorbers come in two major designs monotube or twintube and work by the operation of a piston acting on a hydraulic fluid to “dampen” the motion of the suspension. A piston in a 100% filled tube of hydraulic fluid would be locked and would not move, so there needs to be some reserve for the fluid to go to.

Pictured is a mono-tube shock on the left and twin-tube shock on the right.

Twin-tube shocks use two tubes separated by a base valve on the bottom. The inner working tube is 100% filled with hydraulic fluid with the outer reserve tube being a mix of hydraulic fluid and nitrogen gas. As the inner working piston moves up and down responding to chassis motion the lower base valve allows the extra fluid to move into and out of the outer reserve tube. The pressure of the nitrogen in the outer reserve tube is low, typically as low as 35 psi to as much as 100psi. This eliminates the need to have a highly polished piston bore with a floating piston.

The primary advantage of a twin-tube shock are the lower manufacturing costs because a highly polished piston bore is not needed, the lower nitrogen pressure levels needed and the oil and gas chamber are separated by a valve, so the required amount of stroke is easier to manufacture.

Disadvantages are aeration (foaming of the fluid) is possible since the oil and gas chambers are not fully separated. This aeration is very similar to what is experienced if you’ve ever had brake fade on track and your brake peddle feels “spongy”. This low gas pressure also means the shock is generally very soft. Great for everyday use like for getting groceries or going to work, but not in demanding conditions like track-use.

In the mono-tube shock, pictured above on the left, there is one tube doing all the work. Like in the twin-tube design there is a working piston and hydraulic chamber, but here the reserve chamber is below this working chamber and is 100% filled with nitrogen separated by a floating piston. The working chamber and the reserve chamber never come into contact with each other so aeration cannot occur.

Because we are concerned with performance the mono-tube shock offers many advantages. Because the nitrogen gas is typically at a higher pressure than in the twin-tube design there is additional resistance meaning you can vary the pressure of the nitrogen gas allowing for tunability. The gas itself becomes part of the spring action of the damper compressing over smaller bumps and quicker over bigger hits like the edges of FIA curbing or other bumps on the track improving control and response. This provides the monotubes a better damping force meaning you can tune the shock to work with the spring and also offers better heat dissipation. The monotube shock also has a larger and wider piston valve allowing for a wider area of pressure offering the tuner more precision and consistency in damping force.

A primary disadvantage of the monotube shock are the associated higher manufacturing costs. The gas pressure of the nitrogen under the floating piston needs to be quite high. These pressures can range from 260 psi up to 360 psi. Because of these higher gas pressures over the twintube design, the quality of the seal required on the floating piston and the required highly polished surface inside the piston tube increases manufacturing costs. We are after performance so we are willing to live with this disadvantage.

In the inverted shock the tubes containing the fluid and gas are mounted upside down as opposed to the OE standard shock. In a track condition (which we care about) this moves the fluid and gas away from the hub which can get heated from the brake pad/rotor assembly. This allows the shock to run cooler helping it perform at peak for much longer. It also removes unsprung weight by mounting the heavier tube assembly containing the fluid and gas to the chassis as opposed to the control arms. A downside are the higher costs associated because the entire assembly needs to be larger and the piston rod is housed inside of the threaded base. We are willing to forego this disadvantage because the needed very stiff strut assembly of the inverted shock make it better for track-use because it can take more abuse. It aliso provides better suspension geometry under the heavy lateral and braking loads we see in a road course environment.

Dampers won’t limit the total amount of load transfer through the car, but will affect the amount of time it takes the loads to transfer. Therefore, the car’s behaviour during moments of transition; such as initial brake application, brake release, initial turn-in and application of throttle can be affected by a damper setting change. Shocks allow the chassis tuner to decide how fast or slow in the corner weight is transferred. Track width, center of gravity and cornering force control how much weight is transferred in a corner. And the springs control where weight is transferred, front relative to the rear.

Driver input (initial brake application, brake release, initial turn-in and application of throttle) controls the timing and when weight is transferred, and shocks control how fast or how slow that weight is transferred. Either delaying or speeding up the weight transfer.

If we take the front suspension as an example, the compression (bump) happens when additional load is put on the spring, as when hitting a bump and/or hitting the brake pedal. As the spring compresses in response to this additional load, the compression setting on the dampers provides additional resistance. The rebound motion is simply the spring trying to “rebound” to normal after being compressed, as when the car comes off a bump or the driver releases the brake pedal. Resistance to how fast this happens comes from the damper’s rebound setting.

If you are considering upgrading your shocks AST Suspension needs to be on the short-list. Every AST coil over manufactured is designed specifically with the user and application in mind. Nothing is off the shelf. We design and manufacture the shocks based on the car, driver goals (i.e. trackday/HPDE, time attack or wheel-wheel racing), tire/brake pad combination, any added aero and even driving style of the driver. AST Suspension brings decades of motorsports and suspension/chassis design experience the table. Let us design a coil over you will love, making the car more predictable, giving you confidence.

AST is one of the few damper companies that offer both a monotube design AND an inverted installation. AST offers 3 different coil over models, the 5100 (single-adjustable), the 5200 (double-adjustable) and the 5300 (triple-adjustable). A key design feature of the 5000 Series is its inverted strut design. This makes for a very stiff strut assembly, providing better suspension geometry under heavy lateral and braking loads and reduces unsprung weight with the chassis carrying the weight of the coil over, not the control arms.

Another great feature of the 5000 series shocks is modularity. If you want a double-adjustable or triple-adjustable shock but can’t afford it, simply purchase the 5100 damper, then when you are ready send you shocks to an authorized rebuild center to upgrade them to 5200s or 5300s.

Click here to learn more about the complete line of coilovers from AST Suspension!

For racing tips and special member-only offers and discounts